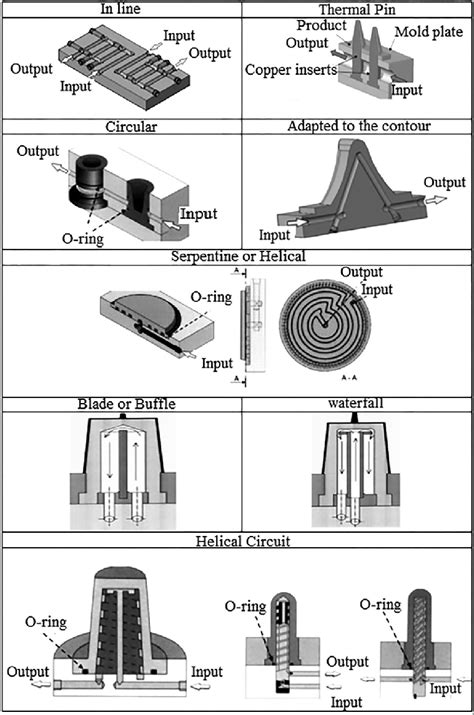

non cooling chanel types | conformal cooling channel design non cooling chanel types The displacements corresponding only to the T-stress have been applied to the . 1. 60. votes. Monogram Canvas. Louis Vuitton. The most famous LV pattern, featuring the LV logo and floral elements, created in 1896. It is instantly recognizable and has become a symbol of luxury. Learn more. 2. 46. votes. Damier Ebene. Louis Vuitton. Introduced in 1888, it features a checkered pattern in brown and black.

0 · types of mold cooling channels

1 · injection mold cooling channels

2 · conformal cooling channels

3 · conformal cooling channel molds

4 · conformal cooling channel design

5 · conformal channels in molds

6 · circular cooling channels

7 · circular cooling channel design

As most of us know, when you reach Tamer Lv 10 in DMO automatically you receive the rewards including more space for you inventory and the storage. well so I reached that level with one of my characters and I didn't receive the notification nor the reward items. Anyone has a solution for this problem?

Conformal cooling (CC) channels are a series of cooling channels that are equidistant from the mold cavity surfaces. CC systems show great promise to substitute .Recently, methods that build better cooling systems by using new fabrication .

There are many types of cooling channel design that are suitable for mould halves .The displacements corresponding only to the T-stress have been applied to the .In addition, the channels are able to achieve uniform mold cooling. In .

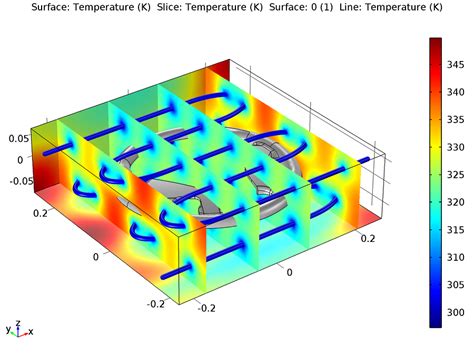

2.3. Boundary condition. The boundary conditions are defined as follows: • Work .Figure 7: Cooling time analysis in DOE- 1 Conformal Cooling Channels with AM .Compared with conventional cooling, conformal cooling can often result in .

This paper presents an automatic method for designing conformal cooling circuits, .The proposed porous cooling passageway design conforms to the mould surface .Determination of the location, number and shape of cooling channels and of the .

Conformal cooling channels allow more precise control of mould cooling, resulting in improved temperature uniformity in the mould, reduced cycle time and enhanced moulded .

types of mold cooling channels

The advent of additive manufacturing paradigm for metallic parts opens the door to cost-effective cooling channel designs via topology optimization techniques. By selecting and .In a nutshell, mold cooling channels play an integral part in enhancing injection molding efficiency. Understanding their basic principles helps to ascertain what type of cooling channel to adopt . Conformal cooling channels (CCCs) are employed to improve the cooling rate due to the equal distance from the mold surface. CCCs play a key role in mold injection .Thanks to 3D printing technology, there are now two different types of cooling channels. Standard/Traditional Cooling. Traditionally, cooling channels were straight lines created by .

Based on the surrogate model, the design parameters of each type of cooling channels are optimized to minimize the part surface temperature variation. At the end of the . 1. Introduction. Recently, additive manufacturing (AM) has emerged as a promising manufacturing method that, in many cases, could replace traditional manufacturing methods [ .

They topologically optimized the multi-branch channels of an impinging water-cooling plate and compared it with the models using straight pipe cooling. Kontoleontos et al. [ .

This review of the literature explores the potentials of liquid micro-/mini-channels to reduce operating temperatures and make temperature distributions more uniform in batteries. . Conformal cooling (CC) channels are a series of cooling channels that are equidistant from the mold cavity surfaces. CC systems show great promise to substitute conventional straight-drilled cooling systems as the former can provide more uniform and efficient cooling effects and thus improve the production quality and efficiency significantly. Conformal cooling channels allow more precise control of mould cooling, resulting in improved temperature uniformity in the mould, reduced cycle time and enhanced moulded part quality. The advent of additive manufacturing paradigm for metallic parts opens the door to cost-effective cooling channel designs via topology optimization techniques. By selecting and assessing proper interpolation and projection schemes, we propose a density-based, adjoint approach for the 3D Navier–Stokes-energy equations.

In a nutshell, mold cooling channels play an integral part in enhancing injection molding efficiency. Understanding their basic principles helps to ascertain what type of cooling channel to adopt per production cycle. Each type is armed with efficient functions to tackle challenges that may arise. Conformal cooling channels (CCCs) are employed to improve the cooling rate due to the equal distance from the mold surface. CCCs play a key role in mold injection productivity by enhancing heat transfer between the CCs and mold surface, which leads to shorter cooling time.Thanks to 3D printing technology, there are now two different types of cooling channels. Standard/Traditional Cooling. Traditionally, cooling channels were straight lines created by drilling or milling into the mold. Standard cooling channels may cross or be enhanced with other devices like bubblers or bafflers. Based on the surrogate model, the design parameters of each type of cooling channels are optimized to minimize the part surface temperature variation. At the end of the paper, design cases are studied to validate the effectiveness of the proposed method.

1. Introduction. Recently, additive manufacturing (AM) has emerged as a promising manufacturing method that, in many cases, could replace traditional manufacturing methods [ 1, 2, 3 ]. The original material shapes for the AM method are powder or wire, and they are melted and adhered to generate the designed forms. They topologically optimized the multi-branch channels of an impinging water-cooling plate and compared it with the models using straight pipe cooling. Kontoleontos et al. [ 17 ] employed the continuous adjoint optimization method to solve the heat dissipation problem based on turbulence model.

This review of the literature explores the potentials of liquid micro-/mini-channels to reduce operating temperatures and make temperature distributions more uniform in batteries. First, a classification and an overview of the various . Conformal cooling (CC) channels are a series of cooling channels that are equidistant from the mold cavity surfaces. CC systems show great promise to substitute conventional straight-drilled cooling systems as the former can provide more uniform and efficient cooling effects and thus improve the production quality and efficiency significantly. Conformal cooling channels allow more precise control of mould cooling, resulting in improved temperature uniformity in the mould, reduced cycle time and enhanced moulded part quality. The advent of additive manufacturing paradigm for metallic parts opens the door to cost-effective cooling channel designs via topology optimization techniques. By selecting and assessing proper interpolation and projection schemes, we propose a density-based, adjoint approach for the 3D Navier–Stokes-energy equations.

In a nutshell, mold cooling channels play an integral part in enhancing injection molding efficiency. Understanding their basic principles helps to ascertain what type of cooling channel to adopt per production cycle. Each type is armed with efficient functions to tackle challenges that may arise. Conformal cooling channels (CCCs) are employed to improve the cooling rate due to the equal distance from the mold surface. CCCs play a key role in mold injection productivity by enhancing heat transfer between the CCs and mold surface, which leads to shorter cooling time.

Thanks to 3D printing technology, there are now two different types of cooling channels. Standard/Traditional Cooling. Traditionally, cooling channels were straight lines created by drilling or milling into the mold. Standard cooling channels may cross or be enhanced with other devices like bubblers or bafflers. Based on the surrogate model, the design parameters of each type of cooling channels are optimized to minimize the part surface temperature variation. At the end of the paper, design cases are studied to validate the effectiveness of the proposed method. 1. Introduction. Recently, additive manufacturing (AM) has emerged as a promising manufacturing method that, in many cases, could replace traditional manufacturing methods [ 1, 2, 3 ]. The original material shapes for the AM method are powder or wire, and they are melted and adhered to generate the designed forms. They topologically optimized the multi-branch channels of an impinging water-cooling plate and compared it with the models using straight pipe cooling. Kontoleontos et al. [ 17 ] employed the continuous adjoint optimization method to solve the heat dissipation problem based on turbulence model.

injection mold cooling channels

High Voltage Transformer Definition: A high voltage transformer is defined as a device that changes high-voltage AC power to low-voltage AC power or vice versa, functioning above 35 kV. Transformer Types: Includes testing, power, HVDC, FACTS, and special transformers, each designed for specific functions and applications.

non cooling chanel types|conformal cooling channel design